News Center

TYSIM CAT Chassis Rotary Drilling Rig Accelerates China-Thailand Infrastructure

Release time:

2025-10-22

Recently, at the construction sites for the Thailand-China Railway bridge project and a major infrastructure program in Chiang Rai Province, the KR220C rotary drilling rig—supplied by Wuxi TYSIM RENTAL & SERVICE Co., Ltd.

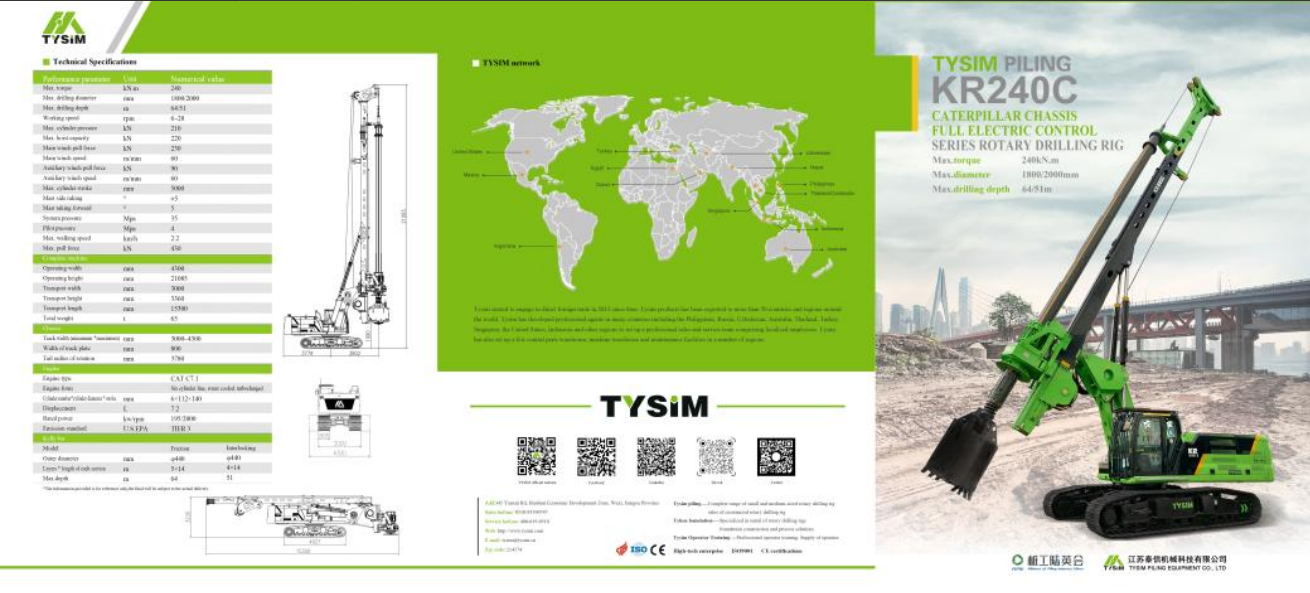

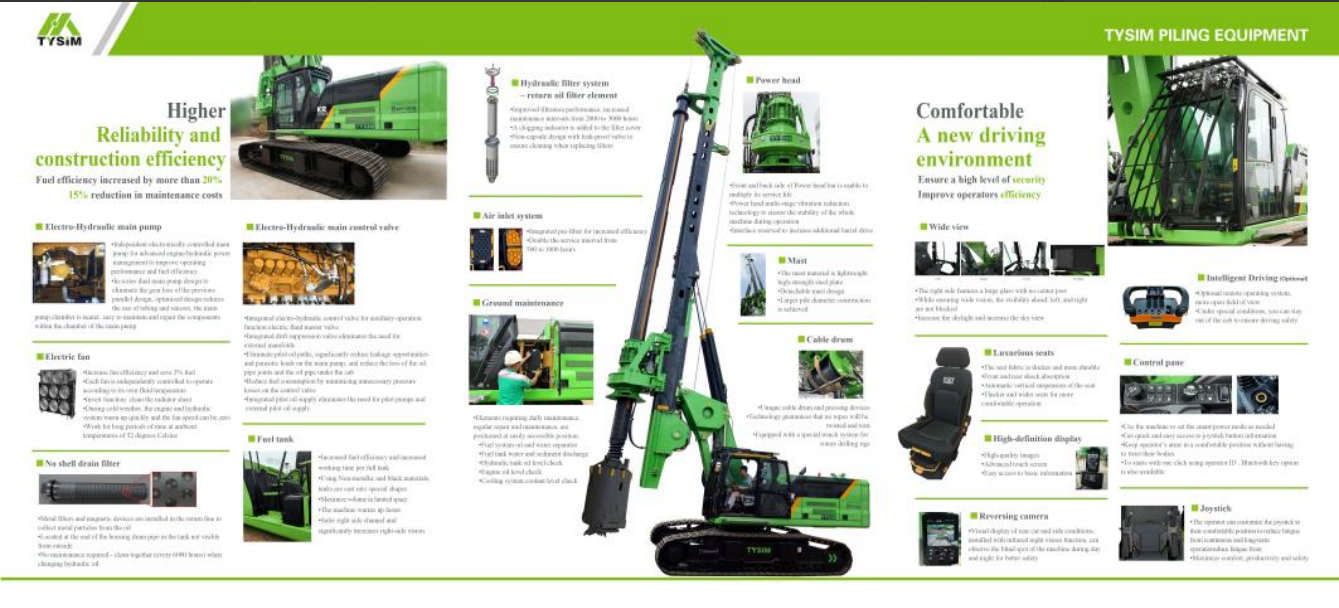

Recently, at the construction sites for the Thailand-China Railway bridge project and a major infrastructure program in Chiang Rai Province, the KR220C rotary drilling rig—supplied by Wuxi TYSIM RENTAL & SERVICE Co., Ltd. (hereinafter referred to as "TYSIM") and mounted on a Caterpillar undercarriage—has become a core asset in overcoming complex geological challenges due to its exceptional performance. This success story not only demonstrates the technical strength of Chinese equipment but also accentuates the comprehensive value of TYSIM's professional rental service for rotary drilling rigs. This integrated model, which combines equipment, technology, and service into a trinity, provides a one-stop solution for international engineering projects.

Dual-Project Campaign: Efficiency Breakthrough Under Complex Geological Conditions

For the bridge pile project of the China-Thailand Railway, three complex geological layers need to be overcome: 1-9m white sand layer, 10-33m muck layer, and 34-39m strongly weathered red sandstone. The piles require a diameter of 1000mm and a depth of 39m. To address these geological challenges, the KR220C adjusts drilling parameters in real time via its intelligent electronic control system: it drills continuously at 3.5m/h in the sand layer without hole collapse; in the muck layer, it uses intelligent hydraulic power distribution technology to reduce the single-pile penetration time by 2.5 hours; in the strongly weathered red sandstone section, it activates the one-click rock entry mode for accurate rock embedding at 1.2m/h. Its construction efficiency is 30% higher than that of traditional equipment, while the sediment thickness is controlled within 50mm and the hole formation qualification rate reaches 100%.

In the same period, the Chiang Rai project requires piles to be 51m deep and 1000mm in diameter, with geological conditions including sand, strongly weathered white sandstone and moderately weathered white sandstone. The KR220C rod-locking drill pipe meets the ultra-deep requirement: it maintains a drilling efficiency of 3m per hour in the surface sand layer, and the verticality deviation is less than 1/300 in the strongly weathered sandstone. For the hardest moderately weathered white sandstone, its 220kN・m of torque, combined with multi-stage shock absorption design, achieves a drilling speed of 0.8m per hour—over 40% higher than local equipment. Eventually, a single unit completed 2 piles (51m deep each) daily, finishing the phased task two weeks ahead of schedule.

End-to-End Service: Highlighting the Core Advantage of Rental

End-to-End Service: Highlighting the Core Advantage of Rental

The high-performance operation of the KR220C is rooted in the full-chain rental service guarantee of "Hardware + Software + Service" from TYSIM. Beyond the robust power provided by the Caterpillar engine and undercarriage, its intelligent electronic control system automatically optimizes torque and pressure parameters for different geological conditions, eliminating inefficient energy consumption. Crucially, TYSIM's rental service extends far beyond the machine itself. The 24/7 backend monitoring system, "TYSIM Cloud," provides real-time status updates and early-warning alerts. Furthermore, TYSIM deploys seasoned operation engineers and after-sales service engineers to the site for on-the-ground guidance, delivering professional parameter calibration and maintenance. This comprehensive support ensured an overall equipment failure rate of below 5% in both major projects, effectively clearing the path for highly efficient construction.

The Value of Rental Services: Empowering International Engineering Projects

The high-performance operation of the KR220C is rooted in the full-chain rental service guarantee of "Hardware + Software + Service" from TYSIM. Beyond the robust power provided by the Caterpillar engine and undercarriage, its intelligent electronic control system automatically optimizes torque and pressure parameters for different geological conditions, eliminating inefficient energy consumption. Crucially, TYSIM's rental service extends far beyond the machine itself. The 24/7 backend monitoring system, "TYSIM Cloud," provides real-time status updates and early-warning alerts. Furthermore, TYSIM deploys seasoned operation engineers and after-sales service engineers to the site for on-the-ground guidance, delivering professional parameter calibration and maintenance. This comprehensive support ensured an overall equipment failure rate of below 5% in both major projects, effectively clearing the path for highly efficient construction.

Related News